OUR NEW HIGH SPEED BLOWER RANGE

Our High Speed Blowers are more efficient, smaller, easier to maintain and save you money every day.

Airtec High Speed Blowers - Big Annual Savings!

AIRTEC AIR SYSTEMS LTD

We have now expanded to a brand new purpose built office/warehouse facility which holds the largest stock of Side Channel and Centrifugal Blowers currently in the U.K. This enables us to offer a fast turnaround for a wide range of our standard products.

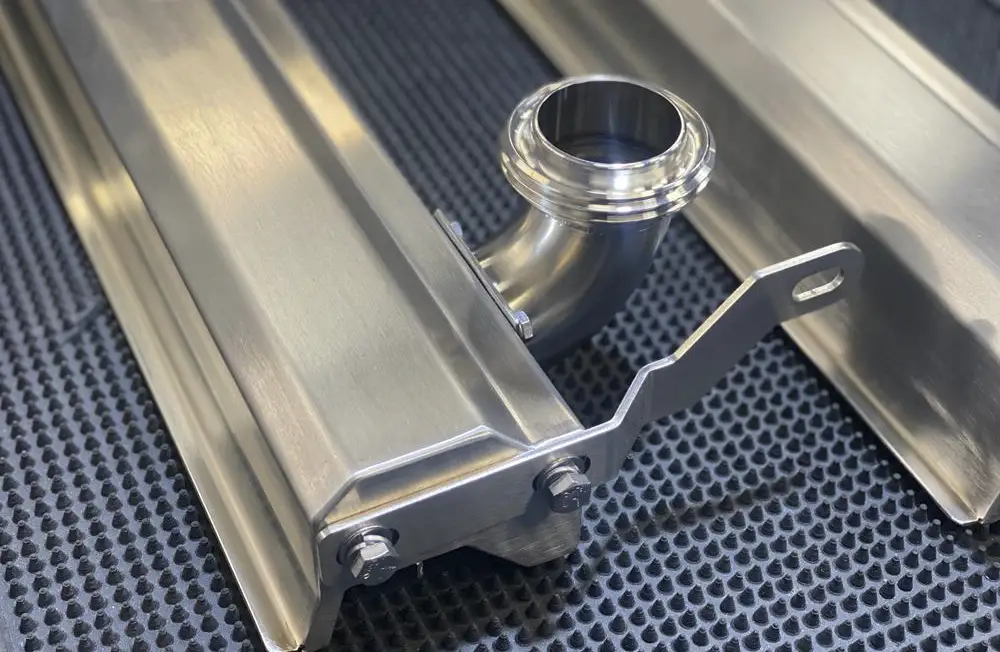

AIRKNIVES

Our Air knives are custom made in the UK. Superb for Air Cutting, & Drying

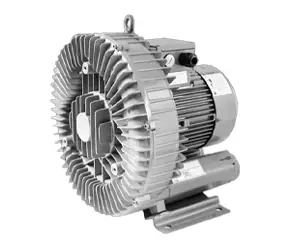

SIDE CHANNEL BLOWERS

Side Channel Blowers move large volumes of air at low pressures

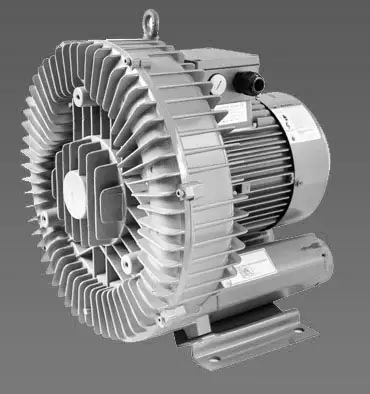

HI SPEED BLOWERS

High Speed Blowers - For medium to high velocity Airknife applications.

CENTRIGUFAL BLOWERS

With robust, corrosion resistant, epoxy resin coated cast aluminium housings

PROCESS AIR HEATERS

Designed to produce a continuous stream of clean, dry, hot, controlled air

ACCESSORIES

Filters, Flexible Hoses, Acoustic Enclosures, Valves, Fittings and more.

PRODUCT OVERVIEW VIDEO

Case Studies & Applications

We've been lucky enough to work with some amazing clients. Whether it's an Air Knife for Aston, or a Drying System for Premier Foods - We've tackled it all.

Meet The Airtec Air Systems Team

Hi there! Our team of experts are waiting to help you with any enquiry, why not drop us a line and we can chat about your project today.

SEND AIRTEC A MESSAGE

CONTACT AIRTEC

News & Resources From Airtec

3 Reasons to Choose Airtec Air Systems

-

By

Airtec

Reasons To Invest in Air Knives

-

By

Airtec

The Importance Of Ventilation in Industry

-

By

Airtec

Avoid issues with oil lubricated machines

-

By

Airtec

Airtec Air Systems Ltd was established in March 2000 after consultation with a number of key customers in the industry, the aim of which was to identify their needs and expectations of a potential new supplier.

GET IN TOUCH WITH THE AIRTEC TEAM

Our experts are waiting in our UK premises to help you. Drop us a line for a 100% obligation free chat about your project and requirements.

SEND AIRTEC A MESSAGE

CONTACT AIRTEC

SOME AMAZING CLIENTS AROUND THE WORLD

We've supplied hundres of clients with Air Systems, from small to large companies, we cater to everyone. Click Here to see more...

GET THE LATEST AIRTEC NEWS IN YOUR INBOX

Will be used in accordance with our Privacy Policy

Share Us!